What is EOQ and Why Do I Need It?

Wrestling with how much to order? Wondering when you should order material? Often times, managing inventory via an Economic Order Quantity, or EOQ, can be a very effective technique. But what is it and how can an ideal ordering point be determined? What follows is a bit of a primer on EOQ’s.

Defining EOQ

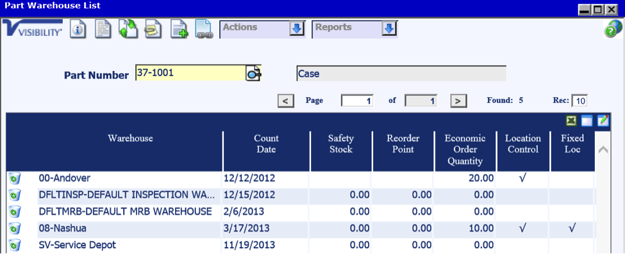

By definition, Economic Order Quantity is a formula used to calculate inventory stocking levels. Its main purpose is to help a company maintain a consistent inventory level and to reduce costs. EOQ uses variable annual usage amount, order cost and warehouse carrying cost. Companies can use the EOQ equation to effectively determine the most cost-effective number of goods to order in correlation to operating costs of the business.

EOQ = 2 *Annual Demand (Usage) * Order Cost / Carrying Cost

Essentially, the method tries to balance the goal of ensuring that there is inventory to satisfy demand while considering the ordering and carrying costs; trying to keep those as low as is possible.

Why is EOQ needed?

Well, inventory is expensive. It’s expense to manufacture or procure and it’s expensive to keep in stock. Whether it is raw materials, Work in Process (WIP) or Finished Goods, companies can use EOQ as an efficient ordering guideline to prevent shortages while not maintaining excess inventories. Economic Order Quantity is often one of many inventory planning techniques available in an inventory control or ERP solution. Other techniques include Reorder Points, Period of Supply, etc.

Interested in learning more about our ERP solution or have a question for us? Don't hesitate to contact us. You can reach us online or give us a call at 978-269-6500.